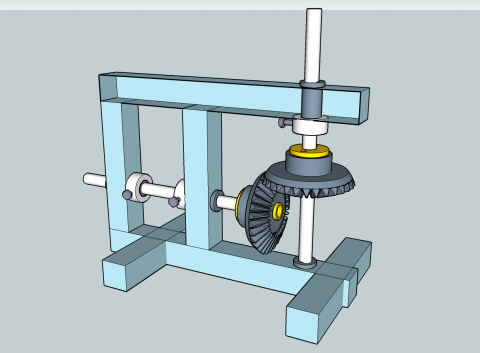

Turnatable Mechanism (Bevel Gears)

This is an illustartion, created using Sketchup (a free 'Auto CAD' type programme from google) of a turntable mechanism being made in the Theatre Metal Workshop at Wimbledon.

The gears are made from Nylon supplied by HPC gears.

The frame that carries all the components is 25mm x 25mm box section steel.

Brass bushes were made on the lathe to fit inside the gears to reduce the size of the hole because they came supplied with a hole too large for the drive shafts we were using. We could of used Nylon but had none at this daimeter.

In the illustartion, the top tube has been cut away to show the solid Nylon bearings that needed to be made to support the drive shaft.

The gears are spaced by bushes that fit over the spare end of the solid bearings. These are held in place with a 6mm bolt threaded through the bush.

Comments

The nylon bevel gears can be supplied by Ondrives ltd, in our precision gear manufacturing dept. if you would like a quote please provide the information to sales@ondrives.com (website: www.ondrives.com ) we are very competitve and can not be beaten for qualtity and price many thanks kayleigh

Thank you very much

Hi Steve,

The bevel gear mechanism is really useful for students of many disciplines, and this is a great illustration. My mechanical box http://process.arts.ac.uk/content/34-mechanical-box illustrates a few other simple transmission methods.

Regards

Paul

Thanks for posting on process.arts, we started the pilot last week, you are the first person who has posted without any directing or prompting from me, was really nice seeing the first post go up independently.

The project is on a six month trial where I aim to highlight and explore its potential and convince the university to support and develop the concept as a more permanent resource, feed back welcome.

Will you be posting pictures of the actual turntable mechanism and its construction, be great to see?

Cheers Chris