Ford 3D printing Innovation Tour at Chelsea College of Arts & ISD PlanEt project presentation

Embed:

We were fortunate enough to see Ford Motors hold their UK stop of their international 3D Printing Innovation Tour at Chelsea College of Arts. Ford were really keen to involve the staff & students in the event and invited students along to be part of the event and presentations.

Chelsea BA Interior and Spatial Design course stepped up to the challenge providing an overview of their PlanEt Project and then considering perspectives of the Ford presentation in terms of how industry 3D printing rapid prototyping techniques could influence the way the students approach design in the future.

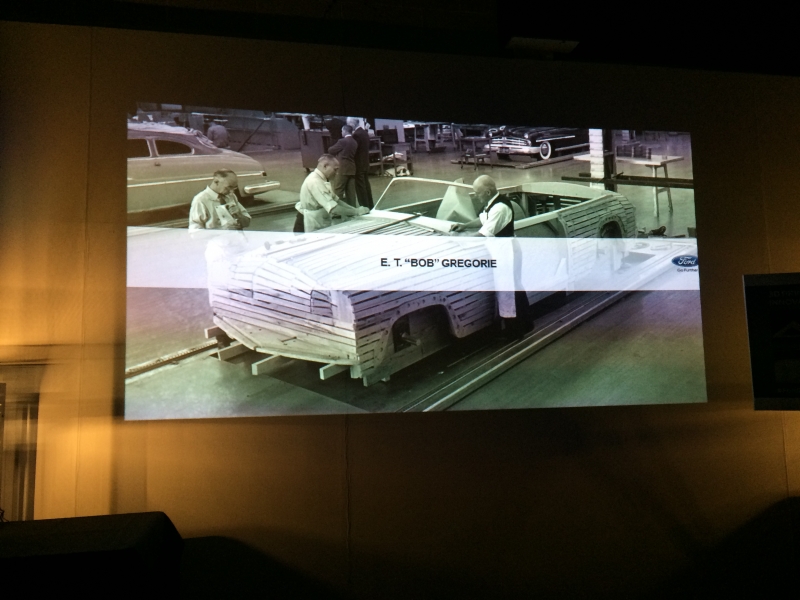

The Ford specialist designers and digital fabrication technicians gave a really interesting overview of industrial 3D printing and rapid prototyping techniques employed by ford since 1988 along side a reflective critique of how the not so rapid prototyping had been carried out in the past.

Fascinating to see how 3D technologies such as virtual reality and 3D printing has informed and enhanced Ford rapid prototyping, providing quick results, new possibilities and new unseen perspectives.

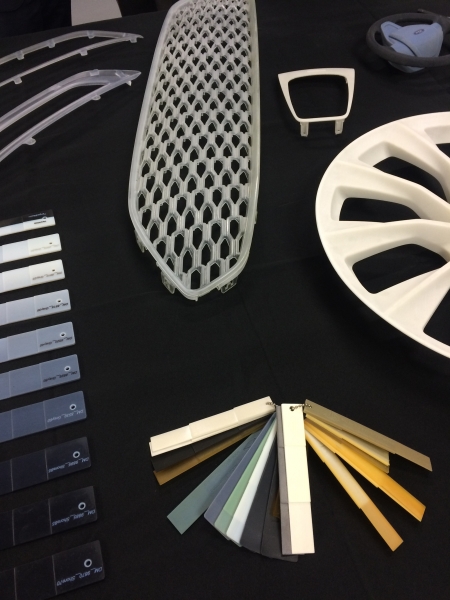

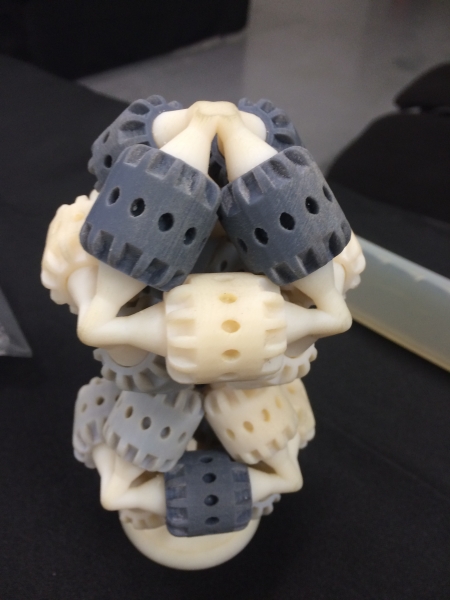

Some images from the event with Ford:

Ford Design staff answering questions from Chelsea BA Interior and Spatial Design course

3D printed objects from Ford Design rapid prototyping studios

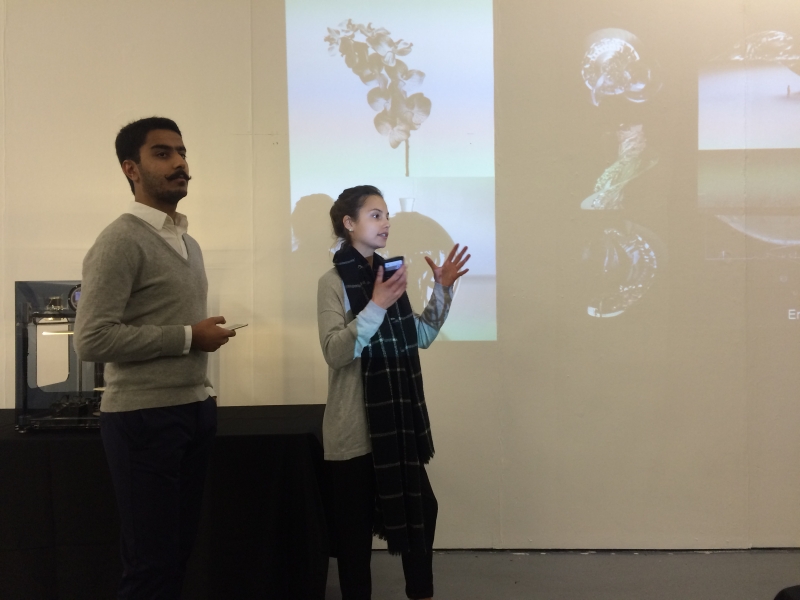

Students from the Chelsea BA Interior and Spatial Design course explaining the PlanEt project to Ford Design

Students from the Chelsea BA Interior and Spatial Design course explaining the PlanEt project to Ford Design

Early prototyping methods at Ford Design

Ford Design

Ford Design

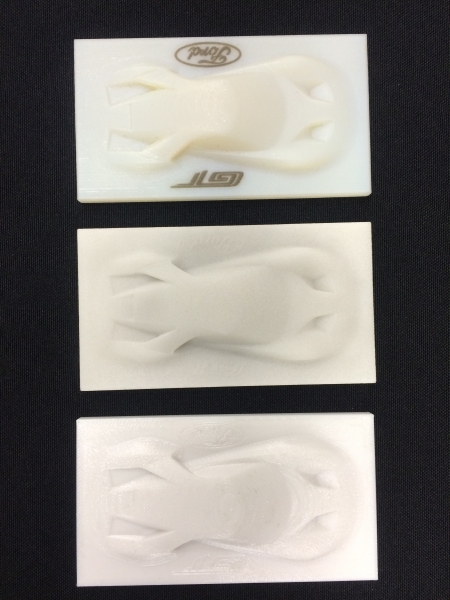

Some samples of the different types of of 3D printing practiced by Ford in their design and rapid prototyping studios from the common to the industrial :

Fused deposition modelling (FDM) & Stereolithography (SLA) more of a 'home' 3D printing standard, an additive manufacturing technology. FDM works on an "additive" principle by laying down material in layers; a plastic filament or metal wire is unwound from a coil and supplies material to produce a part.

To the more industrial and high end, high quality 3D printers such as:

Polycarbonate 3D Printing - known for its strength and transparency

Selective Laser Sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power source to sinter powdered material (typically metal)

Resin: There were some nice examples of resin 3D printing

Also See: Ford have also offered some car designs files to be printed on your own 3D printer - http://3d.ford.com/

Video recording by Ian Samels